In 2012, GA Pet Food embarked on a journey that would revolutionise the pet food industry. True to GA’s core values, we invested significantly in technology that would not only provide our partners with unique positioning and selling opportunities but also, crucially, supply pets with a diet rich in nutrients from freshly prepared ingredients.

The result of this ambition was the development of Freshtrusion®.

Freshtrusion® – A Scientific Support Paper

Dr Adrian Hewson-Hughes, a Nutrition, Food Safety and Innovation Advisor, has authored a scientific support paper explaining how Freshtrusion® enables GA Pet Food to create the world’s finest pet food.

You can read the support paper by clicking the button below.

From Farms and Fisheries We Know and Trust

The Freshtrusion® journey begins at our trusted farms and fisheries, where we source only the finest fresh meats and fish, thereby providing our partner brands with compelling stories of provenance and traceability.

Using our own refrigerated transport to maintain the highest quality conditions, we collect these meats and bring them to our production site in Lancashire, England, where they undergo extensive quality testing before being incorporated into our partners’ unique recipes.

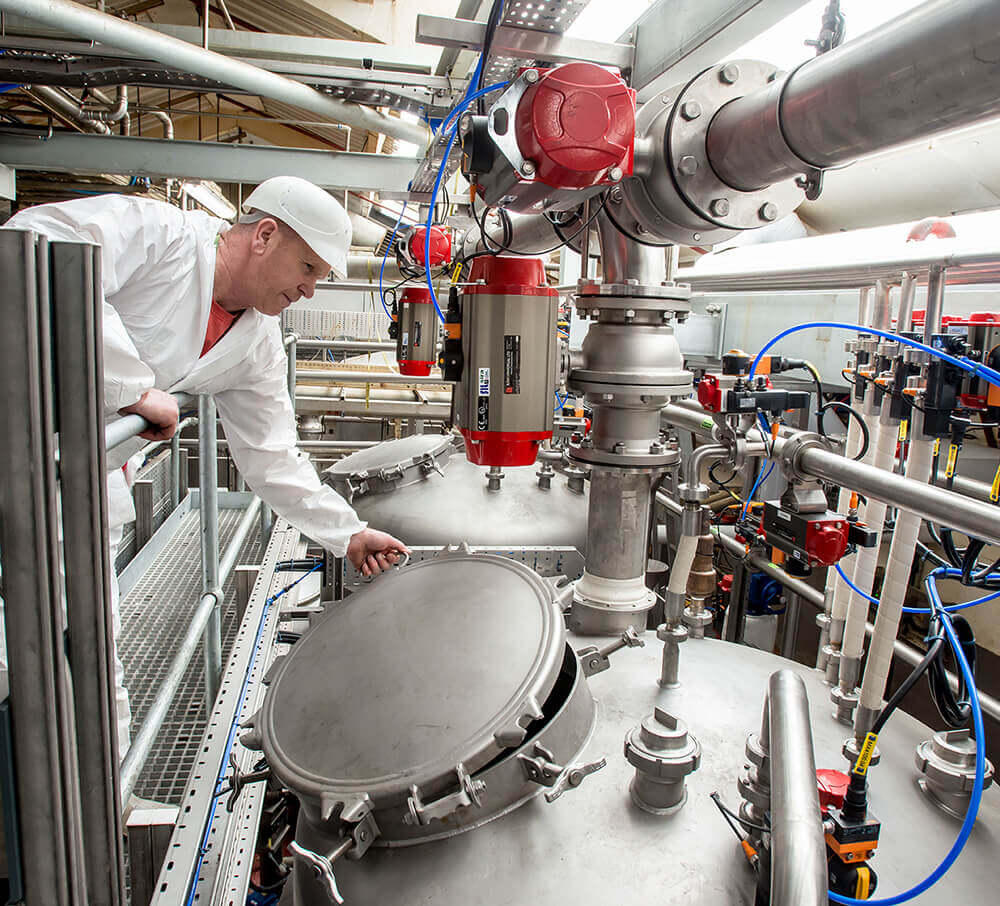

The Meat Kitchen

Within our on-site Meat Kitchen, we gently cook each meat at approximately 82ºC (180ºF) to protect the proteins and ensure maximum digestibility and nutritional value for the pet. Using world-leading technology, we also reduce the moisture content of the freshly prepared meat, enabling us to include higher amounts of fresh meat in our market-leading recipes.

In addition, we produce high-quality oils from our fresh ingredients of known provenance and add these to bespoke recipes, providing further unique selling points.

Freshtrusion® Means More Fresh Meat Inclusion

We understand that pets recognise that fresh is best; that is why fresh meat is our passion. Through our unique process, we develop recipes that offer outstanding selling points in the marketplace, boasting the highest levels of fresh meat inclusion and providing pets with the most flavoursome and nutritionally beneficial mealtime.

Category 3 Meat Meal

Freshly Prepared Salmon

Protected Protein

Freshtrusion® Protects the Protein

Animal material used to produce dried meat meal is not collected fresh at the source, nor is it transported using refrigerated containers. Instead, it is gathered from various locations and sent at ambient temperatures to a rendering plant, where it is processed at very high temperatures (300ºF/150ºC) to extract moisture, separate fat, and kill bacteria.

This process can denature the protein and result in a product that is less digestible and, therefore, of lower nutritional value for the pet. In contrast, our gentle cooking approach ensures the proteins remain protected, thus providing increased bioavailability.

Denatured Protein

Traditional Category 3 Meat Meal

Freshly Prepared Meat

Human-Grade Quality Oils and Fats

At GA Pet Food, we press our own oils on-site in small batches using dedicated equipment that operates similarly to a kitchen salad spinner, whereby the oil is extracted from the meat.

This process enables us to coat the kibbles with exceptional, high-quality fats and oils – akin to those used in human foods – and provides full traceability back to the source, whether that be the farm, fishery or boat.

The marketing potential, along with exceptional palatability and traceability, is second to none. These oils are not the usual high-temperature rendered ‘pet-food-grade’ oils; they are so fresh that laboratory testing reveals little to no sign of oxidisation or ageing.

Benefits of Freshtrusion®

We believe your brand, your customers and the pets you feed deserve the best. That is why we have developed our unique Freshtrusion® technology and have worked closely with the University of Nottingham for further analysis and testing.