The History of GA Pet Food

From Arable Farmers to the World’s Finest Private-Label Dry Pet Food Manufacturer

The History of GA Pet Food – From arable farmers to the World’s Finest private label dry pet food manufacturer

1972

Thomas Bracewell acquired Plocks Farm over 50 years ago as a mixed arable and livestock farm.

1992

GA Pet Food (GA) started as Golden Acres in 1992. Roger Bracewell was farming and practising as a land agent with his father, Tom.

In the sheep shed at Plocks Farm, the then farm manager, John Blackett, took some of the wheat that GA was growing on the 2,500-acre farm and poured it into a small extruder driven off a tractor’s PTO shaft. Out came a ‘meal’. GA could sell the meal for more than the wheat, which is how it all began!

1995

In 1995, GA Pet Food added a Wenger Inc. wet extruder and moved part of the recently closed BOCM Midge Hall Mill, using farm labour to provide the milling and mixing machinery needed to produce the dry raw ingredients.

Shortly after, in 1998, GA added a Wenger TX144 Twin-Screw extruder, further cementing the long-term partnership with Wenger Inc.

2000

The company installed a new mill with a Wenger 185 Optima Single-Screw extruder. The dried products were packed by automated Cetec 400 and 700 packing lines.

GA’s continuous investment in the business had proven to be a tremendous success. In 2000, GA Pet Food manufactured 500 different types of extruded pet food, catering for a range of animals from dogs and cats to small animals. These products were sold to 350 different partners.

2007

The Meat Kitchen was installed to cope with the increased demand for fresh meat inclusion.

2011

GA Pet Food consolidated its finished product warehousing from five separate sites into two dedicated 200,000 sq ft distribution centres at R2 and D2 in Chorley, Lancashire.

This enabled the development of a specialised facility to store the finished products and the empty packaging in a fully automated warehouse. This allows the finished product to be collated and despatched to meet the partners’ exact requirements, 24 hours a day, seven days a week.

2012

GA Pet Food commissioned a Wenger Thermal Twin 3630, which can manufacture very high levels of fresh meat into premium dried pet food without the use of dry meat meals.

The meat refrigeration storage capacity increased to cope with the demand for fresh meat inclusion.

2014

The opening of the new Microbiological Laboratory provides zero tolerance for mycotoxins, Salmonella, and Enterobacteriaceae.

Innovative microbiological and indirect analyses ensure the safety, digestibility, and nutrient quality of every product.

2014

Freshtrusion® is born—a world-first in dry pet food technology.

Freshtrusion® technology allows more fresh ingredients to be used in dry pet foods than any other extrusion system in the world, including fresh meat and now fresh vegetables, herbs, and botanicals.

2015

Two additional biological filter beds were installed to complement the existing three, purifying the air before its reuse in the manufacturing process or release into the atmosphere. An advanced odour abatement system significantly reduced odours, minimising the environmental impact.

Electric forklifts were implemented in the distribution centre to reduce dust and noise pollution, improving the working environment for GA’s colleagues.

2022

In May 2022, GA Pet Food held an opening ceremony for the £100 million Ingredients Kitchen, officially opened by Councillor Alistair Bradley, Leader of Chorley Council. An Open Day for the Ingredients Kitchen was also held to celebrate the collaboration with world-leading companies and invite colleagues and families to be part of the celebration.

Tours were provided to all colleagues and their families, with dedicated tours for the younger family members to witness the innovative robots in operation.

Compared to its humble beginnings in 1992, GA Pet Food now employs over 650 colleagues, producing and selling more than 80,000 tonnes per year of the world’s finest dry extruded pet food, exporting to 50 countries worldwide.

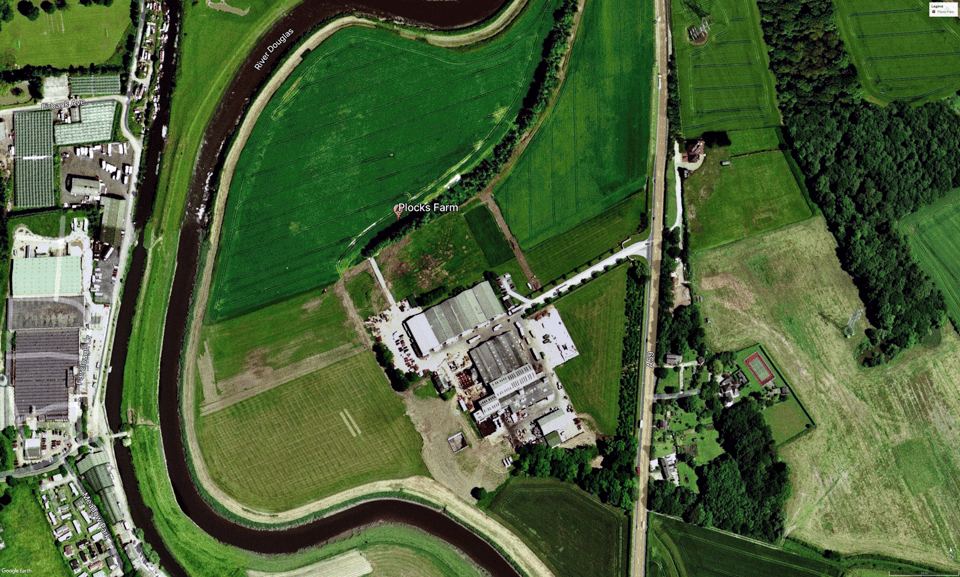

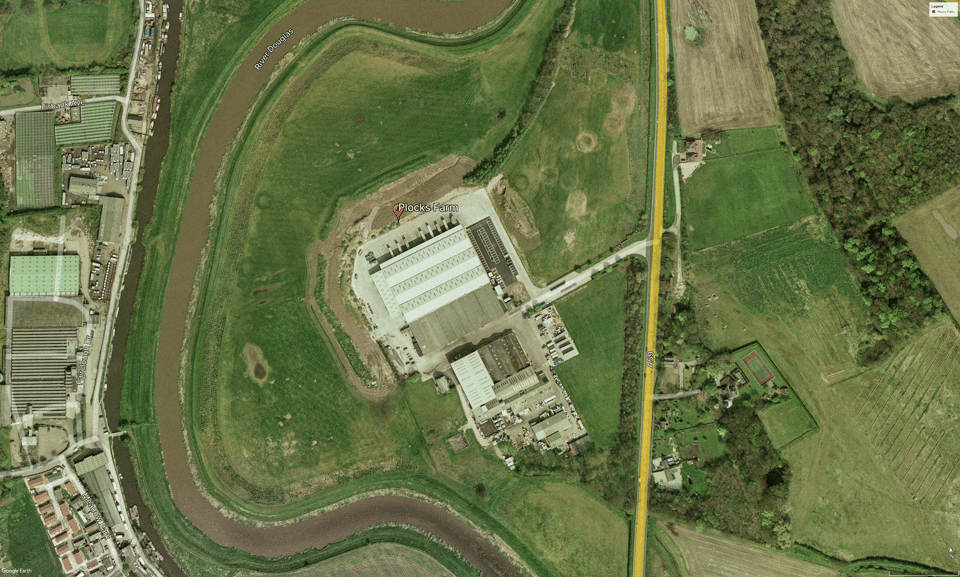

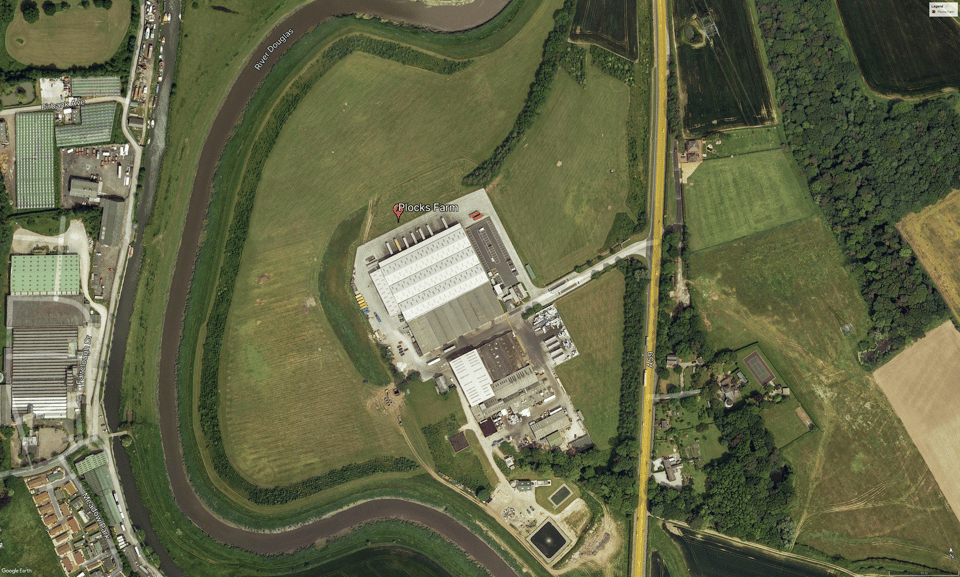

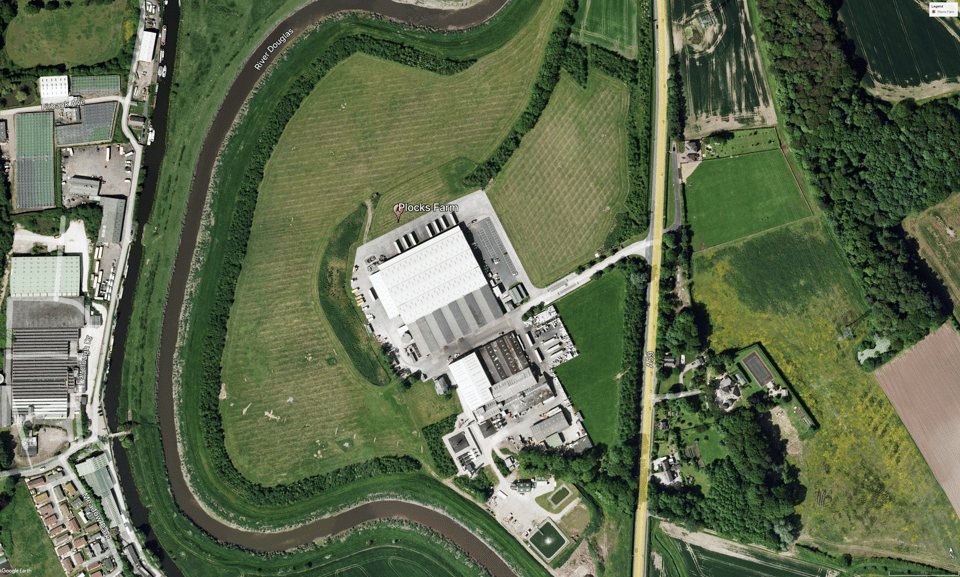

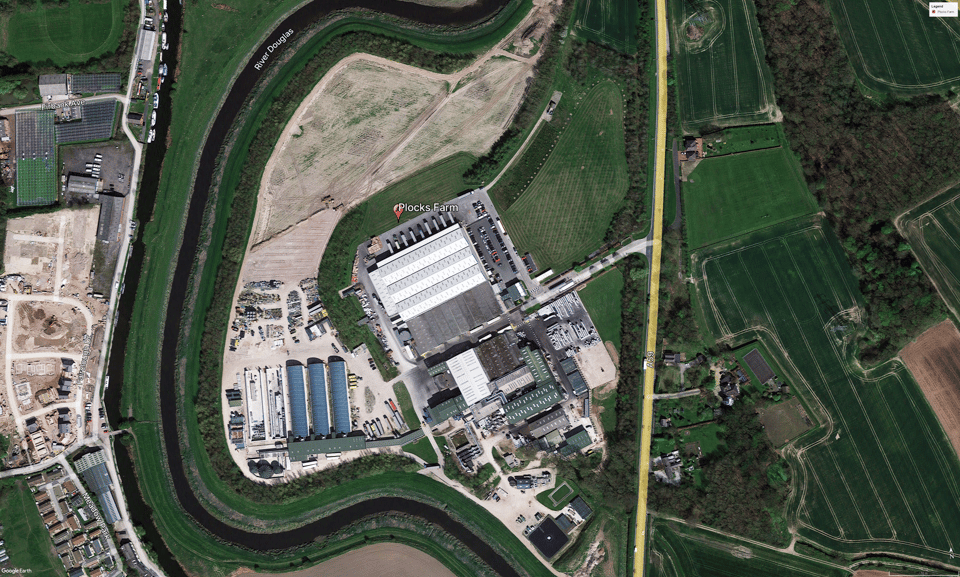

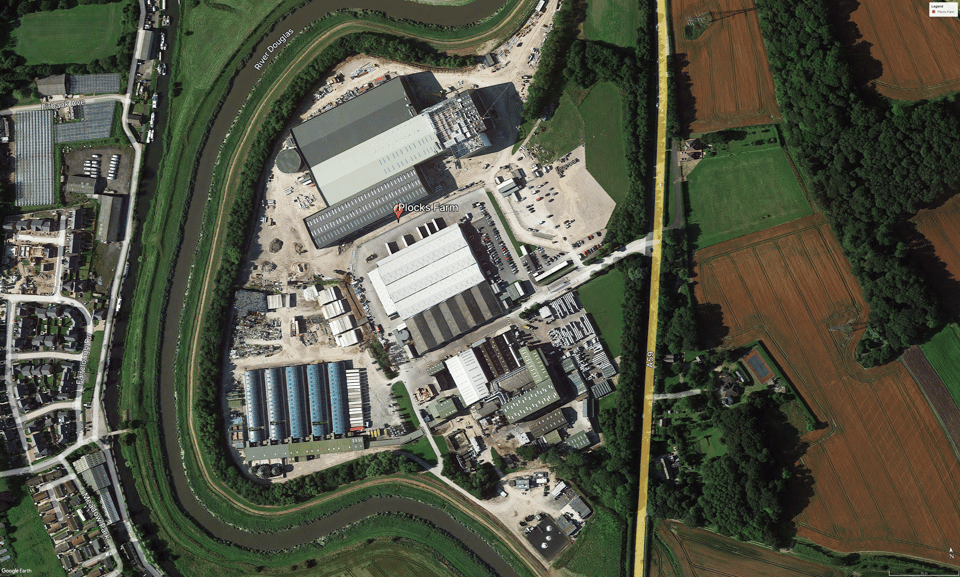

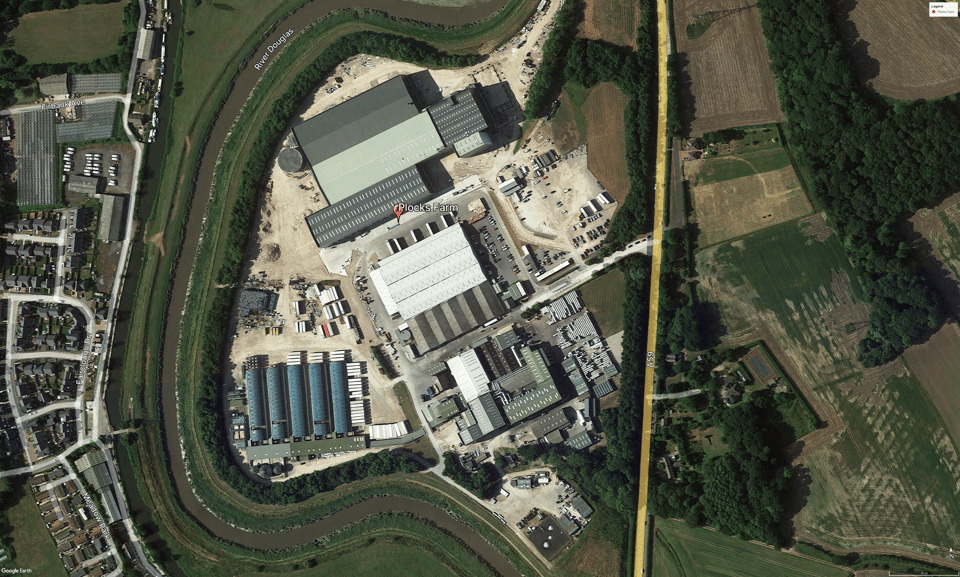

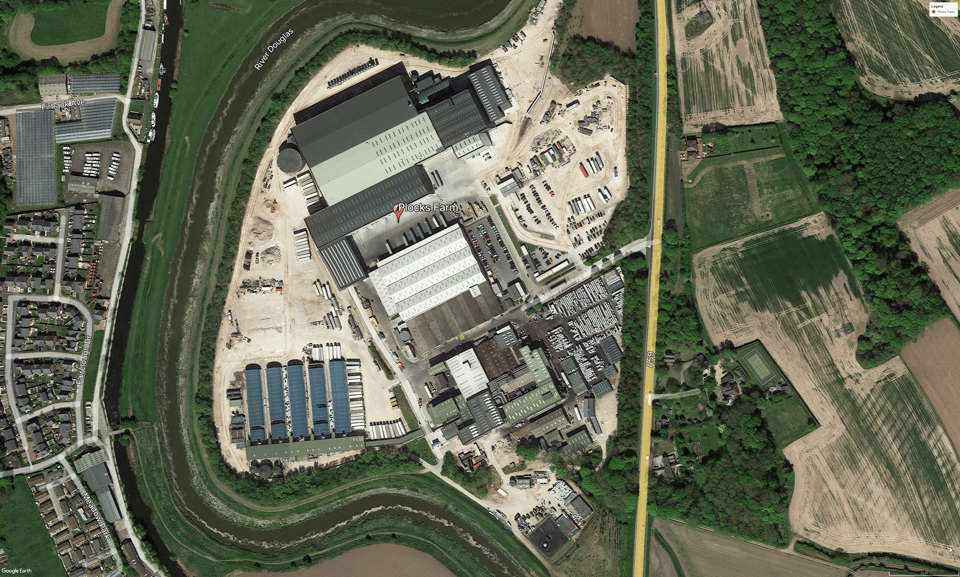

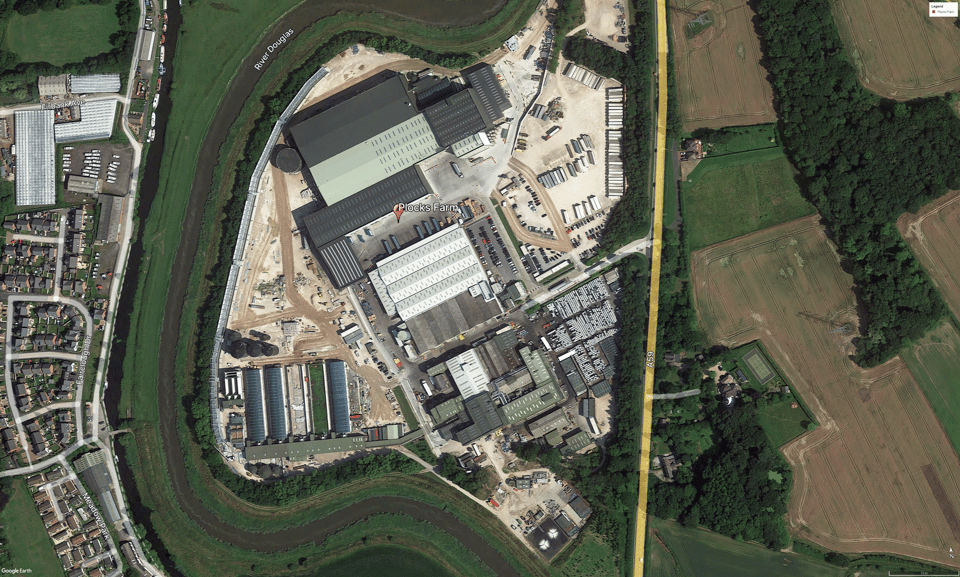

From 2000 to 2021 – A Visual History of Plocks Farm

To the right is a short visual history of our Plocks Farm manufacturing site from 2000 to 2021, demonstrating GA’s continuing growth and investment.